What Are Backorders?

Backorders occur when a customer places an order for a product that’s temporarily unavailable but will be delivered once stock is replenished. For shoppers, this usually means a longer wait between the purchase and delivery date. For businesses, however, backorders provide an opportunity to secure revenue in advance, maintain steady cash flow, and forecast future demand. On the flip side, delayed restocking can create operational challenges if not managed properly.

For a more detailed understanding of how businesses manage such situations, explore E-Commerce Fulfilment.

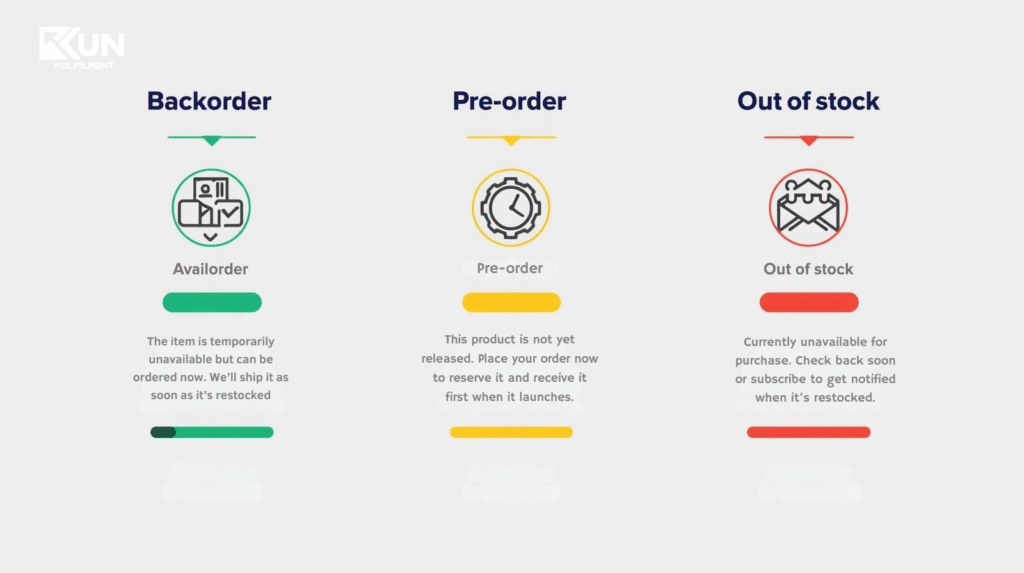

Backorder vs Pre-order vs Out of Stock

While these terms may sound similar, each reflects a different stage of inventory:

- Backorder: The product is normally in stock but currently unavailable for immediate shipping. Clear communication about expected delivery time builds trust.

- Pre-order: The product hasn’t been released yet. Businesses often use pre-orders to gauge demand and allow customers to reserve upcoming products.

- Out of Stock: The product is entirely unavailable and cannot be purchased at the moment. Some businesses pause listings temporarily, while others discontinue them.

If you want to strengthen your delivery strategy, take a look at how improving the order fulfilment process can help.

Common Causes of Backorders

- Transport and Supply Chain Delays

Port congestion, shipping container shortages, or global disruptions like the Red Sea crisis can slow down the movement of goods. - Manufacturing Disruptions

Equipment failures, raw material shortages, or seasonal closures such as Chinese New Year can delay production. - Human Error

Overestimating stock levels or underestimating supplier timelines can lead to overselling. - Sudden Demand Surges

A viral trend or influencer promotion can create a sales spike that outpaces your inventory. - Damaged or Unsellable Stock

Quality issues or damaged goods can lower available stock and lead to instant delays. - Inventory Discrepancies

Selling across platforms like Shopify, Amazon, or WooCommerce without centralized control often causes overselling.

To prevent such disruptions, many brands partner with 3PL providers to stabilize their supply chain and scale efficiently.

Should You Allow Backorders?

Allowing backorders can be a strategic move when managed effectively. It keeps sales flowing, captures customer demand, and reduces the risk of missed revenue.

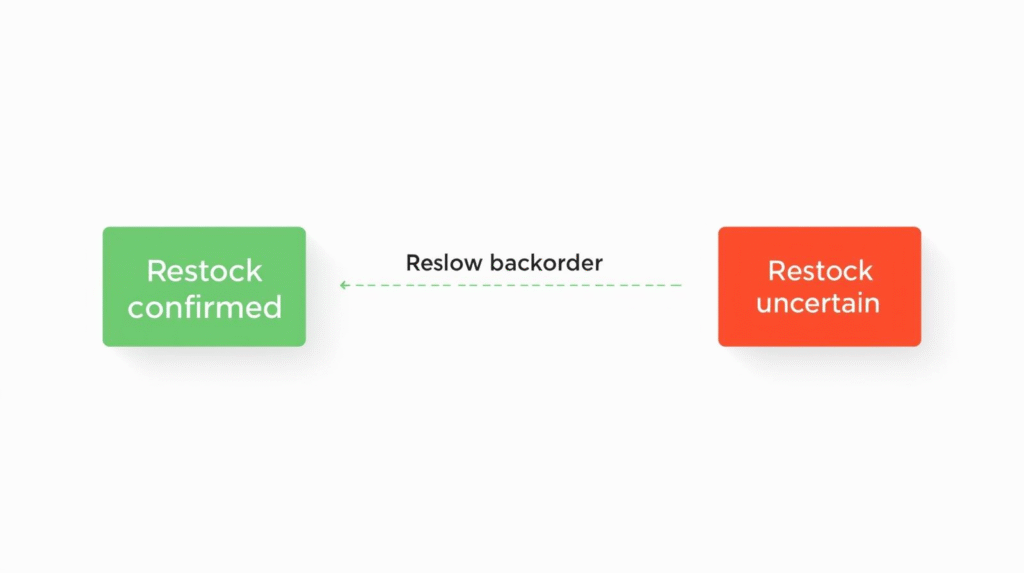

Allow backorders when:

- Restocking is confirmed and expected soon.

- Delivery timelines are communicated clearly.

- Your fulfilment system is capable of handling delays smoothly.

Avoid backorders when:

- Restock dates are uncertain.

- Customer trust and experience could be affected.

A strong fulfilment strategy can make this process more reliable and transparent.

How to Reduce Backorders

- Automate Reordering

Setting automated reorder alerts helps ensure your stock never hits zero. - Maintain Safety Stock

Holding extra inventory cushions against demand spikes and supplier delays. - Work with Multiple Suppliers

Having alternate sources shortens lead times and keeps your supply chain agile. - Audit and Forecast Regularly

Consistent inventory audits combined with accurate forecasting help balance demand and supply.

For a deeper look at how logistics can prevent stockouts, check out 3PL services.

How to Manage Backorders Effectively

A structured backorder management process ensures smooth customer experiences. Here’s how to handle it effectively:

- Clearly label “Backordered” products with estimated delivery dates.

- Segment delayed orders in your fulfilment system.

- Notify customers proactively about restock updates.

- Batch shipments to minimize additional handling.

Many businesses simplify this with smart warehouse systems and automated notifications, similar to solutions offered by 3PL warehouses.

Final Thoughts: Turning Backorders into Opportunity

Backorders don’t always need to be viewed as a problem, when supported by real-time tracking, flexible supplier networks, and reliable fulfilment partners, they can actually become a competitive advantage.

By strategically managing backorders, businesses maintain sales momentum and strengthen customer trust even during stock shortages.

To build a more resilient and scalable system, explore how 3PL logistics can power your entire supply chain.